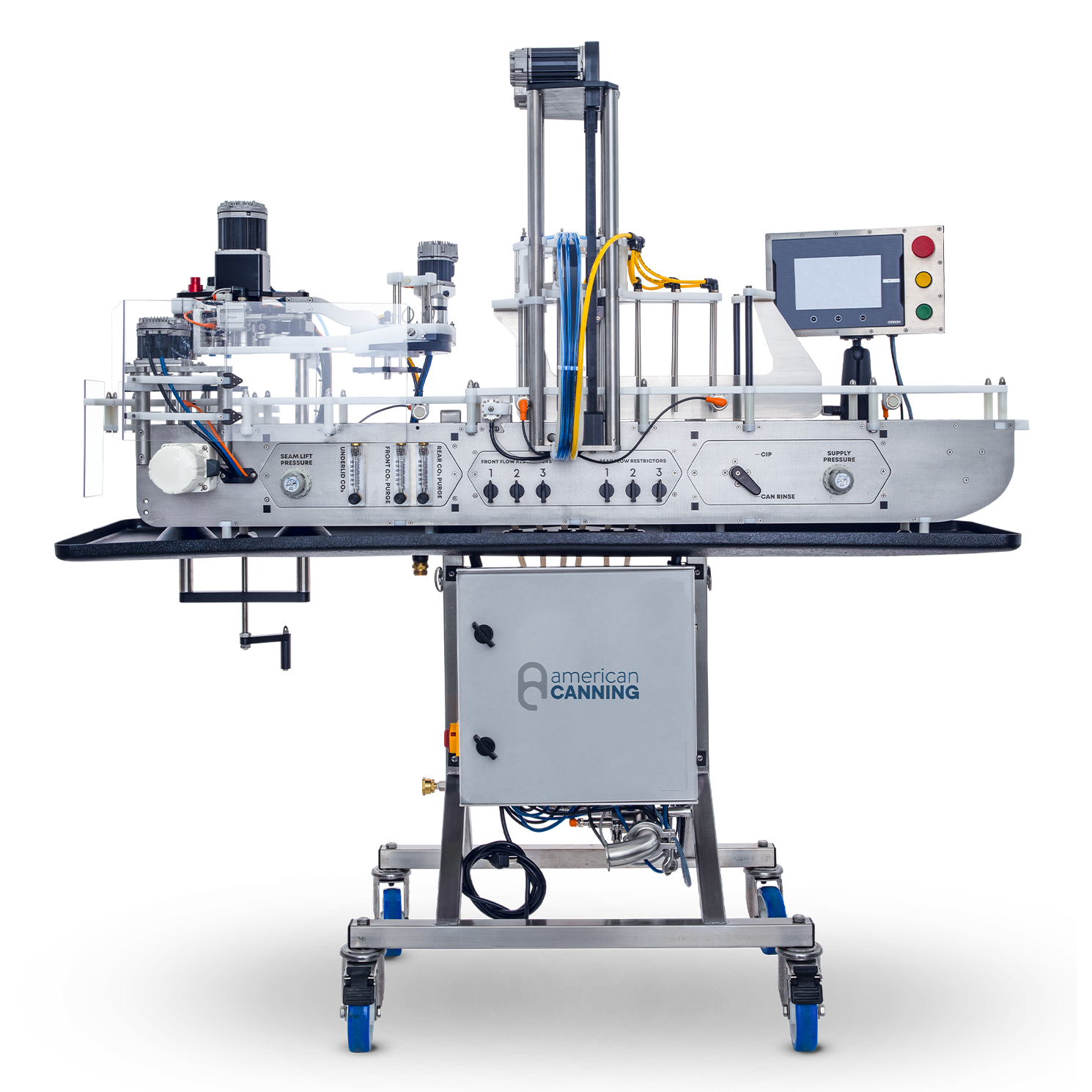

American Canning makes some kick ass equipment for a great price. Parts/service are best in class, not to mention the equipment is compact and works amazing. If you need a part 9 out of 10 times they ship it the same day and you’re back up and running in the AM.

Carrying the Load of Can Carrier Application

Save wrists and optimize production personnel using the PTA Handle Applicator. The PTA is an off-packing solution that automates applying PakTech® brand can carriers so operators have the ability to focus on more quality-driven activities like filling. Users can quickly and easily switch between 4-packs and 6-packs using provided stop blocks; change kits are available for standard, sleek, and slim diameter cans. Whether the goal is increased convenience or sustaining off-packing at speeds greater than hand-applying will allow, the PTA provides a quick return both on investment and morale.

Features

- 120+ cans per minute

- 4-pack and 6-pack configurations

- Easy height change for multiple fill volumes

- Integrated dead plates for near instant setup

- Compact 54” x 20” footprint; deck height made to order

- No additional installation or conveyance required

- Mobile-friendly (casters) or stationary frame

Specs

Crafted in The USA

Every machine we offer is designed and manufactured with pride in Austin, Texas, showcasing the best of American ingenuity and quality. Opt for American Canning and support excellence in local manufacturing, guaranteeing high-performance equipment for your beverage needs.