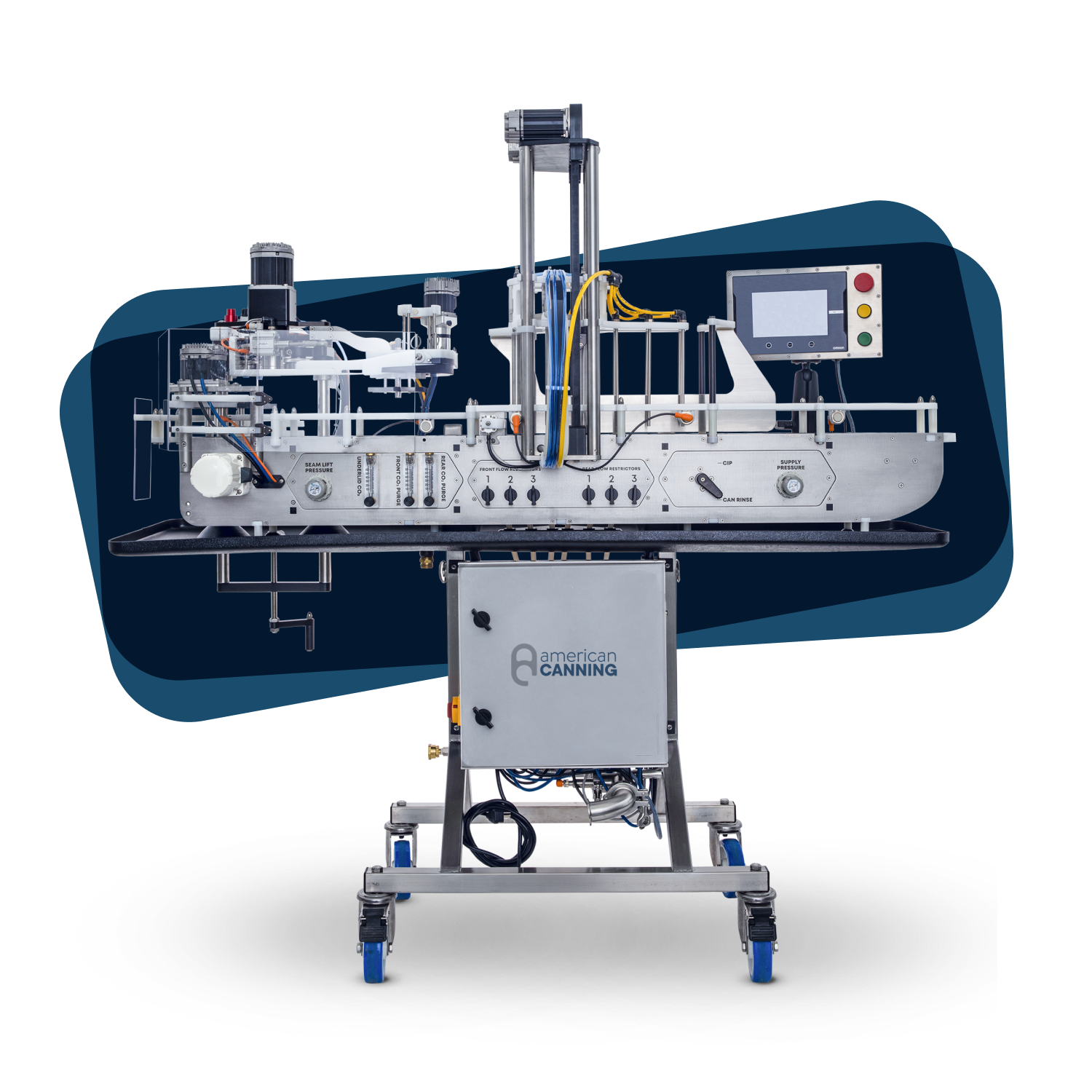

The Machine to Flock to

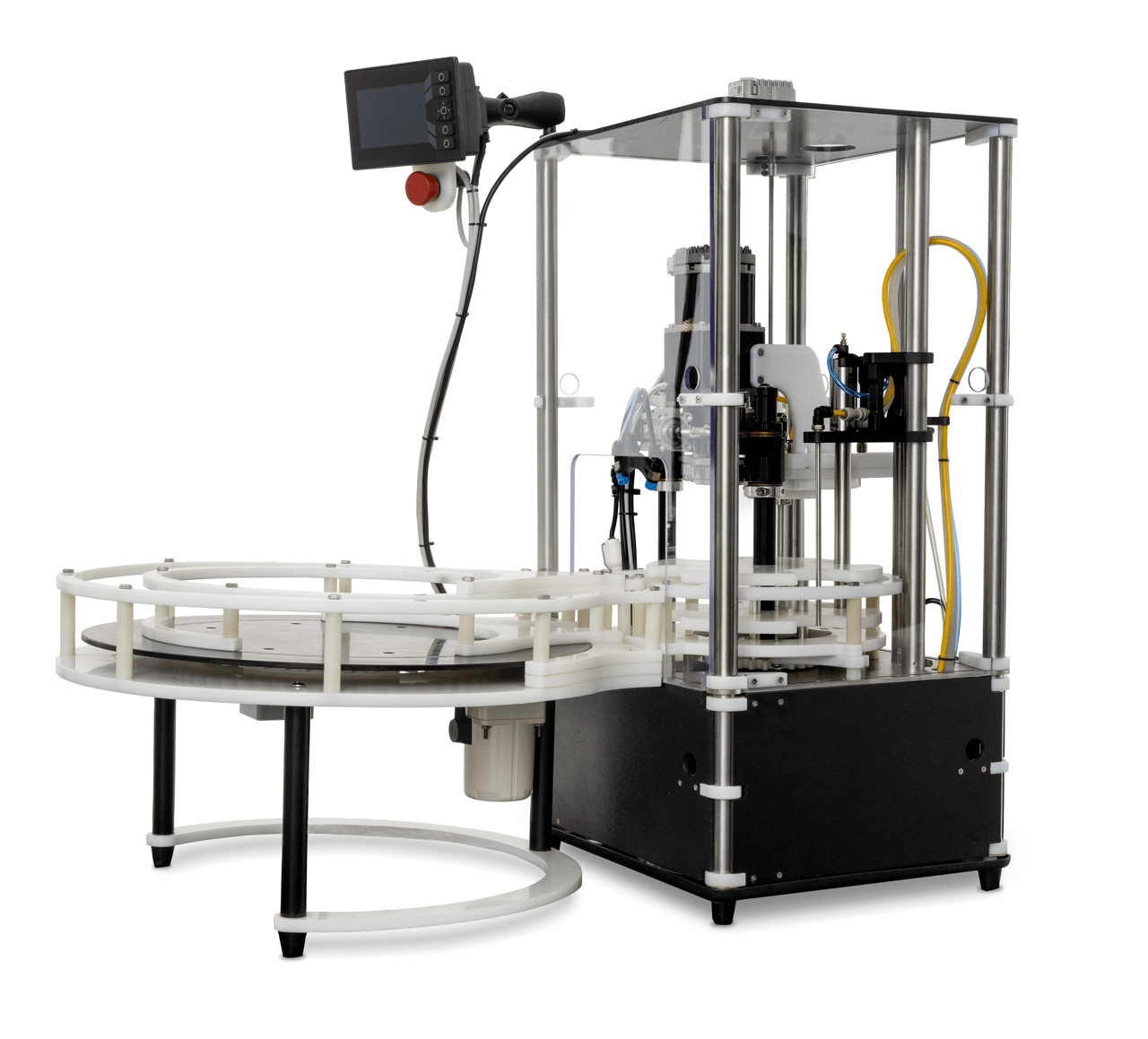

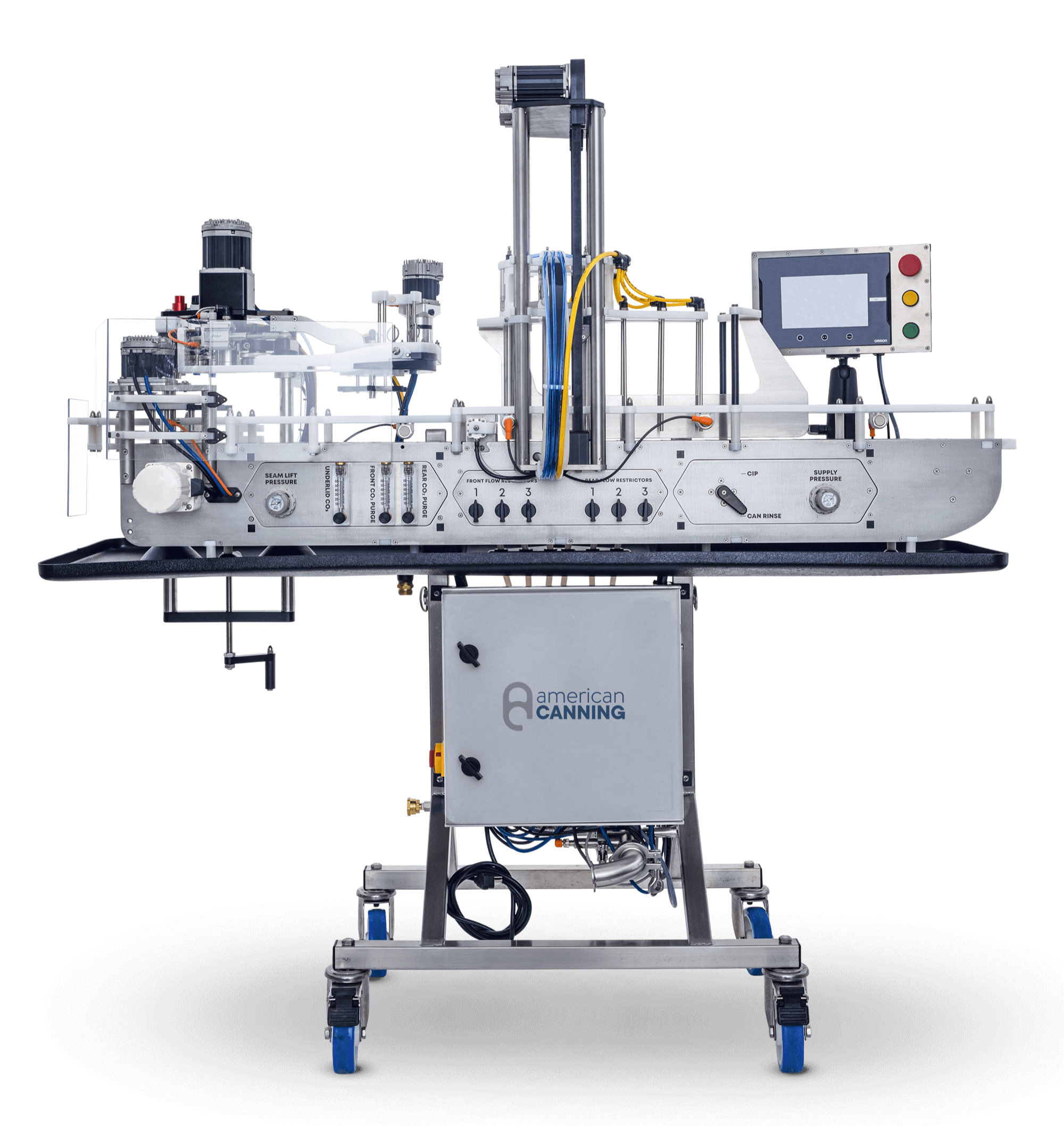

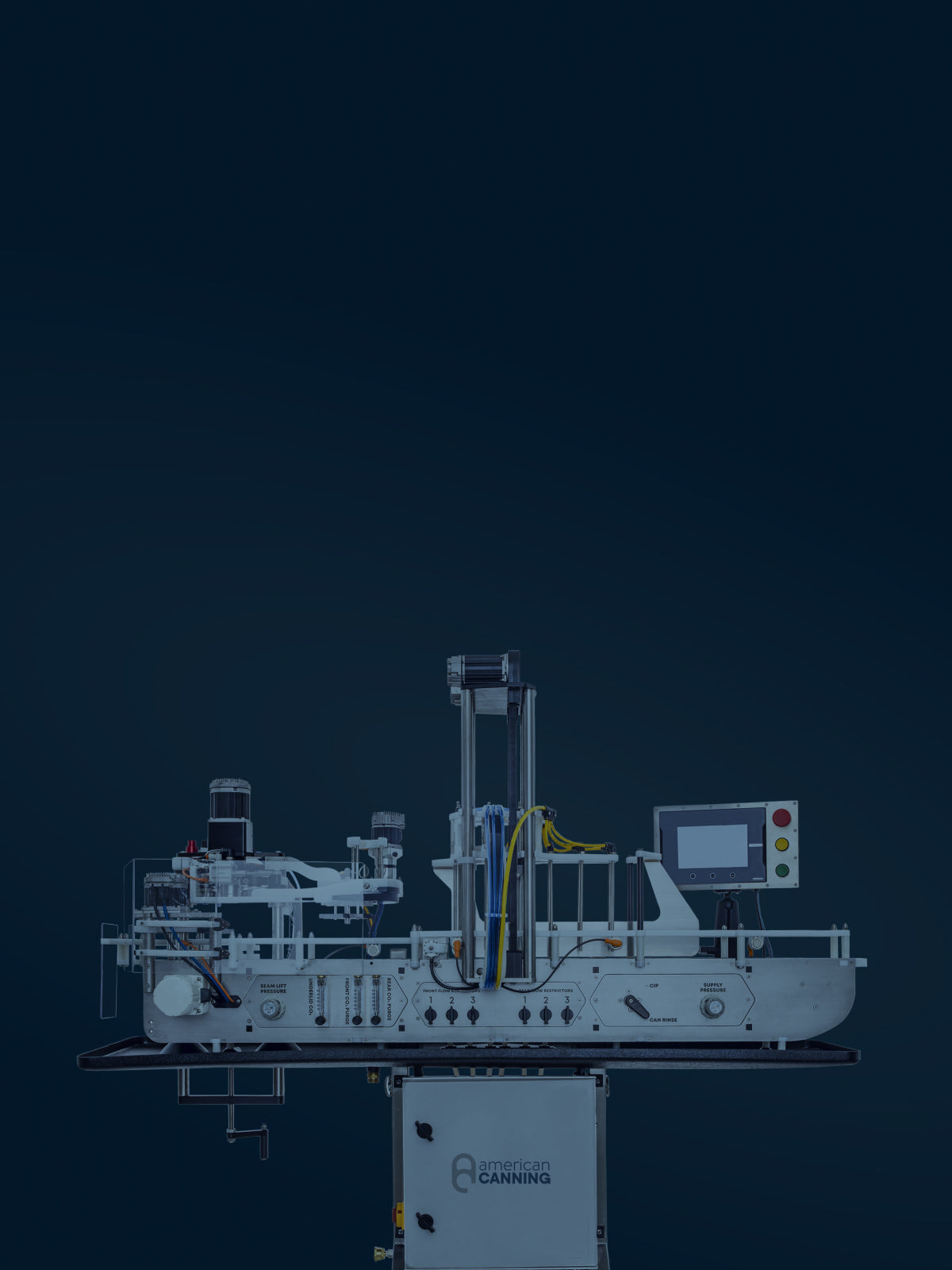

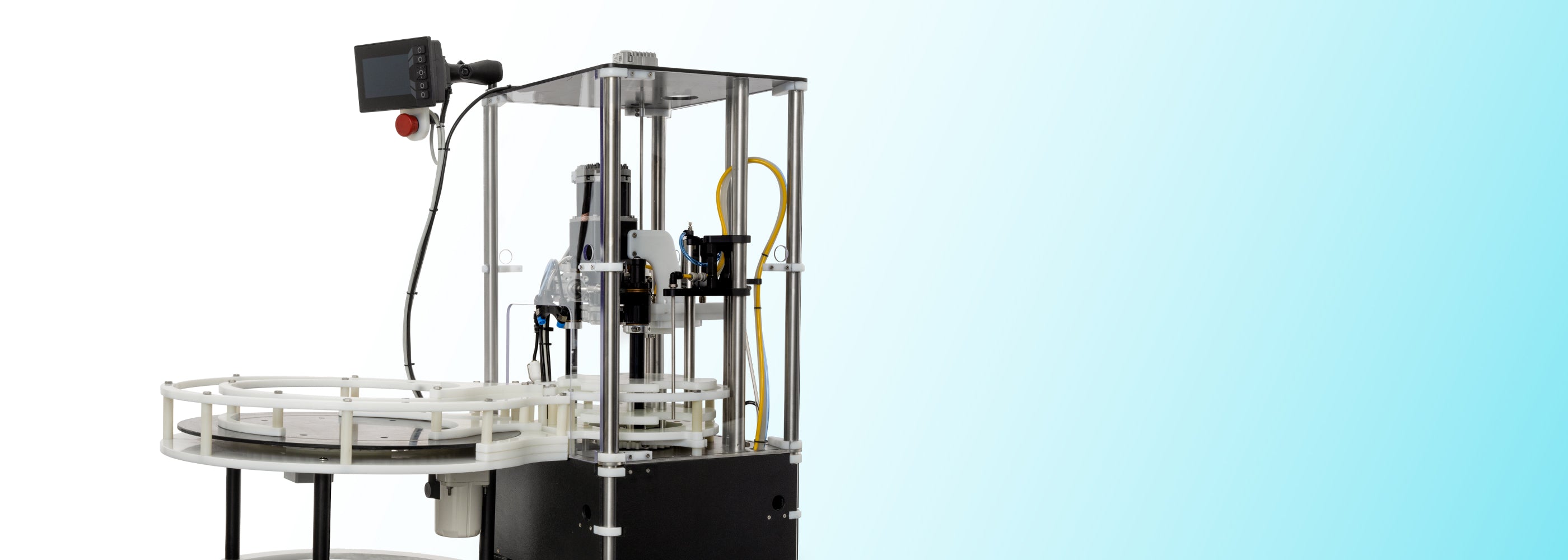

AT-6: Filler/Seamer

Reliably packaging at 60 cans per minute, the AT-6 offers unparalleled speed for its compact footprint (65” X 23”) allowing users to establish or expand their packaging operations without having to compromise on quality or space. While the calling card of the AT-6 is the ability to fill a can per second, its dual-lane setup allows users to start as low as 30 cans per minute and grow at their own pace. Surprisingly for a machine of its power and speed, the AT-6 is easy to move and simple to maintain. American Canning’s newest machine release, encapsulates years of packaging learning surrounding speed, scale, and precision control – all within a cost-effective, compact, easy-to-approach, easy-to-maintain design.