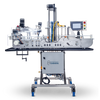

AT-6 Filler/Seamer

Making a collaborative decision?

Share this product page with a colleague.

The brand-new American Canning AT-6 offers speed and precision never before seen in such a compact and easy-to-use machine. Whether you are updating your mobile canning fleet, or upgrading your in-house canning operation, you’ll be sure to save time and space with the user-focused and compact design of this machine.

A 6-head, automated, atmospheric pressure filler, the AT-6 can crank out 60 cans per minute with ease and has reached speeds beyond 60 cans per minute under ideal conditions. Dual three-head fillers operate out-of-phase of each other minimizing transport time ensuring minimal dissolved oxygen pickup and smooth rhythmic operation. The AT-6 fillers are servo-driven for precise travel control and valve open/close timing, with a high degree of repeatability for consistent high-quality fills.

American Canning Lid application technology is unmatched in the compact filler market. Inspired by the lid applicator mechanisms used in high-speed rotary fillers, this servo controlled mechanism maximizes control and minimizes waste. Precision jet underlid gassing gets CO2 right where it’s needed to flush out any lingering oxygen. A low-lid-stack sensor with automatic machine stop ensures you don’t end up with a table full of lidless cans when your lid supply runs out.

The Seamer on the AT-6 is the tried and true, highly rigid, super compact unit found on the American Canning CP-4 and AT-1, tuned to operate at the higher thruput speeds of the AT-6. Servo actuated seamer index gives speed and power to move cans quickly and precisely, minimizing seamer idle time, increasing thruput, and reducing waste.

The AT-6 filler runs any commonly available beverage can and height changes are completed in seconds without any tools. While diameter changes do require some change parts, serviceability and ease of changeover on this machine allow a diameter change to be done in less than 15 minutes.

Features:

- Precision-Adjust flow restrictors provide fine-tuned control of product flow

- Stainless steel fill valves for long service life and easy serviceability

- Built-in tank pressure control system

- Rotary-style lid applicator with underlid gassing minimizes dissolved oxygen pickup

- Long-life, high-precision seamer tooling with ceramic bearings extend maintenance intervals

- Hand crank seamer height adjust for rapid, tool-less can height change

- Integrated post-seam rinse removes excess product from filled/seamed cans

- Post Rinse Blower knocks off excess moisture with minimal compressed air consumption

- Integrated drain pan and splash guarding for minimal operating mess

- Automatic CIP cycle makes cleanup a snap

Recommended Add-ons:

- Video Jet date code printer

- Spare parts kit

- Easy CIP kit

- Can diameter change kit (if packaging more than one can body-diameter)

- LN2 doser (for still product)

Lead Time:

- American Canning is committed to short lead times for all machines. Based on demand and number of machines per order, lead time will be 6 weeks plus transit. Please contact sales@americancanning.com for specifics.

The Complete Canning Suite

Product Specs

Speed: 60 CPM

Can Body Diameters & Fill Volumes: 211,204 and/or 202

3.44” (8oz Standard) – 7.40” (19.2oz Standard)

*Can diameter change parts are available at an additional cost

Operating Footprint: 65" x 23"

Power: 120VAC - 5.4amps